We're your product design team

our Capabilities

What We DO

Our Design Capabilities

When it comes to building great products, design is the most important “feature.” We are creating products meet the needs of our clients through business strategy, user experience design, data analysis and prototypes. VitaCare is capable of providing design from concept to detail mechanical & mold design.

product development processes

Our engineering capabilities cover six major development process which can help you to turn your idea into a product.

Industrial desig

focus on appearance, functionality and manufacturability of a product. We are capable of providing ID according to your concept or ideas.

Mechanical Design

means the design of components and systems of a mechanical nature—Our skilled Mechanical Engineers will provide the optimal design for mass production in our Assy line.

CMF Design

which stands for Color Material Finish Design. During the project developments, we need to communicate more precisely with clients so that there’s no room for misinterpretation of product image.

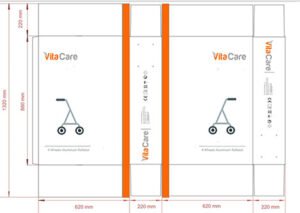

Packaging design

includes choices in material, colors and font that are used on a box. The well-made calculation on dimension of box is crucial for container loading quantity, we can assist you to do the better packaging design.

Prototyping

is an effective way test designs quickly and improve them in an equally timely fashion. It also allows us to communicate in an intuitive and user experience way to make sure product features and functions run as good as designed.

Molding

and tooling are the key to make quality parts (Quality parts equal quality products). Our experience molding and tooling makers provide the cost-effective mold-making service which help you to build premium products over competitors.

Our manufacturing Capabilities

We provide reliable, professional manufacturing process for our clients. To make sure products quality conformity, we created Standard Operating Procedures as a guideline for each product, the formed guidelines for practicing the VitaCare’s Quality principle in our manufacturing activities.

Metal Processing

When it comes to metal processing, we are expert in the filed of Carbon Steel and Aluminum alloy materials.

Welding

Our skilled welding technicians excel in both steel & aluminum welding job which will guarantee the quality of finished products.

Surface treatment

Powder coating, Liquid coating & Anodizing are often applied to healthcare products surface of a material to make it better in some way.

Plastic Processing

Plastic parts assembled in the product are produced by Injection molding, Vacuum forming and rubber.

Fabric Processing

Sewing and High Frequency welding are two major processes of fabric involved in our production.

Assembly

Sewing and High Frequency welding are two major processes of fabric involved in our production.

Manufacturing processes

Five Phases of Product Development

Plan

Communication with clients, marketing research and define project

Design

Product Industrial Design & Mechanism Engineering Verification

Development

Prototyping & Molding Verification

Validation

Developed Product In-House Test & Engineers Pilot Run Production

Production

Pilot Run Production & Mass Production